Introduction to SGP and PVB material properties:

As a world-renowned chemical technology company, DuPont has launched a series of glass laminated products to meet the rapid growth of the market for safety glass and the needs of new standards to improve the safety, durability, and aesthetics of glass. The products, technologies and final evaluation systems provided by DuPont effectively meet the above needs, thereby promoting the development of the entire safety glass industry.

1. DuPont Butacite® polyvinyl butyral interlayer (PVB) has been continuously improved over the past 67 years and has become the leading safety laminated glass

The preferred material for glass, it provides many advantages for laminated glass: safety, anti-theft and anti-riot, noise reduction, energy saving and sunlight control, prevention of fading of indoor colored materials, aesthetics, etc.

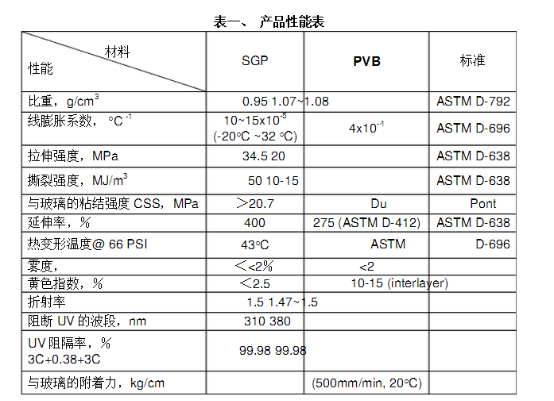

2. DuPont SentryGlas®Plus (SGP) interlayer film is a laminated glass interlayer film recently developed by DuPont Company with major innovative technology. SGP surpasses existing technology and greatly expands the performance of laminated glass. The tear strength of SGP is 5 times that of ordinary PVB, and the hardness is 100 times that of ordinary PVB. SGP's high strength, high transparency, durability, various structures and flexible installation enable it to easily adapt to the latest and most stringent requirements of today's construction market. Compared with ordinary laminated glass, SGP laminated glass can improve the performance of bulletproof glass and reduce the thickness of laminated glass to a certain extent.

SGP is specifically designed to meet the needs of today's construction industry. It has the same shattering safety and fragment retention capabilities as PVB, but can greatly improve the impact resistance, anti-theft and anti-riot performance and disaster resistance of safety glass; to keep the glass intact in the frame, it can be harder and stronger SGP interlayer film; it is suitable for ceiling glass because it has more stringent strength and deflection requirements in terms of safety during use and after breakage. When the temperature of laminated glass rises, it has a more stable and longer service life, as well as excellent weather resistance and edge stability.

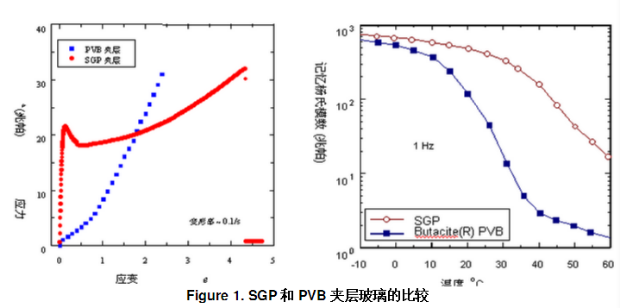

•SG P is a viscoelastic material with high tear strength (5 times that of PVB film)

•Critical temperature of glass ~ 55°C (hardness 30 – 100 times that of PVB film)

•SGP laminated glass is harder than PVB laminated glass

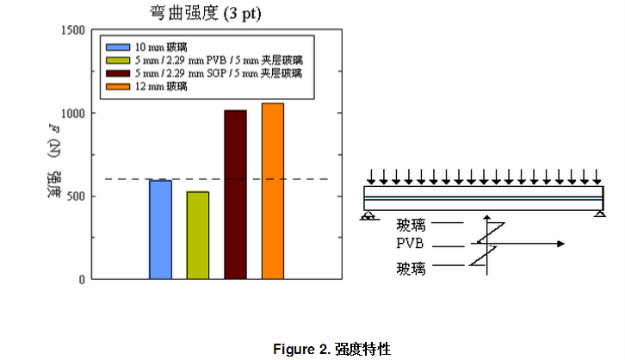

•SGP laminated glass has almost the same bending strength as a single piece of glass of the same thickness

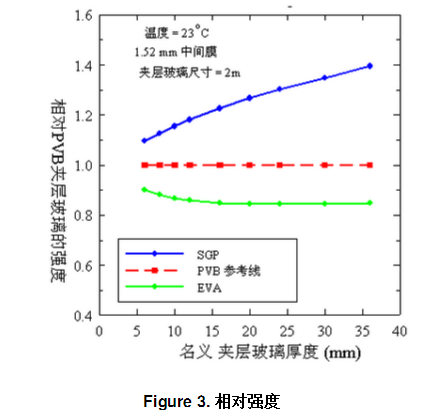

•Compared with other interlayer film laminated glass, SGP laminated glass has more

High strength performance. It can effectively reduce the thickness of glass, especially for thick laminated glass. Particularly beneficial for point-supported glass.

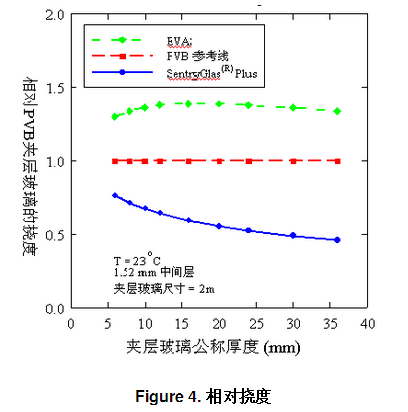

•Compared with other interlayer film laminated glass, SGP laminated glass has

Higher rigidity. Helps reduce glass thickness. DuPont can provide information on performance and design.

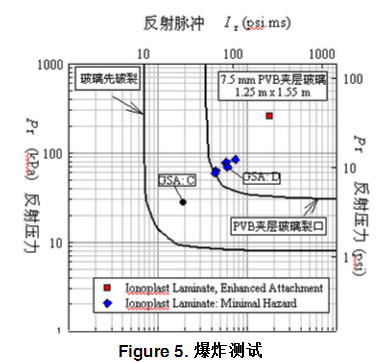

•37.8 psi (261 kPa) - 258 psi.ms

(1,779 kPa.ms) Addresses the U.S. Department of State’s embassy security and security requirements

•More cost effective than glass polycarbonate cladding structures

•Extensive weather resistance testing

- Natural exposure to the sun for more than seven years at Florida test site - Photo anti-aging test in Arizona

• ASTM Xenon Simulation

• SGP does not have edge defects that sometimes occur with traditional PVB laminated glass

•No change in color and haze

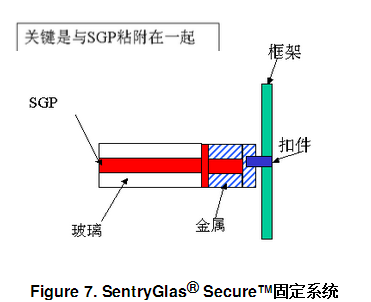

• The bonding strength between SGP and metals, such as aluminum, improves the performance of glass after breaking.

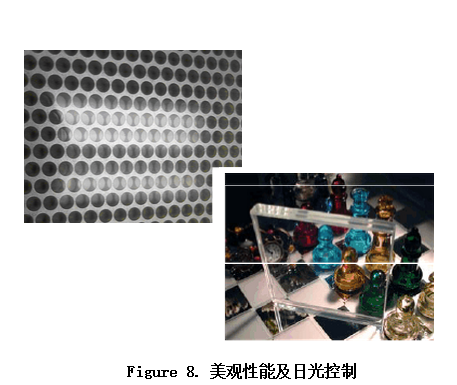

• Design diversity and beauty. In the entire system, the middle layer becomes the basic structural unit.

• Shanghai Oriental Art Center, SGP sandwich drilled stainless steel plate

• Transparent effect after combining SGP with ultra-white glass

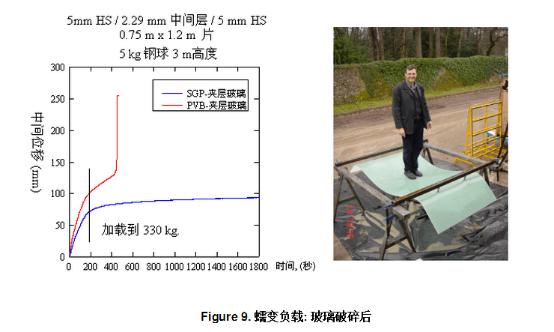

•Test specimen, horizontal plate surface, pre-fracture treatment, central load, four-sided support

• Main manifestations of test failure: falling out of the frame, damage and tearing of fixed parts

• The tear resistance energy of the film is an important indicator of its impact resistance

•Impact resistance is inversely proportional to bonding strength

•The shedding of the film is bound to involve the stretching of the film and the loss of energy (similar to CMCs)

• The performance of broken glass is determined by the plane displacement of the broken laminated glass due to the influence of the larger film modulus.

• Increased hardness and filament strength provide advanced performance

Literature excerpt from DuPont product description