- Home

- >

- Products

- >

- ionoplast interlayer

- >

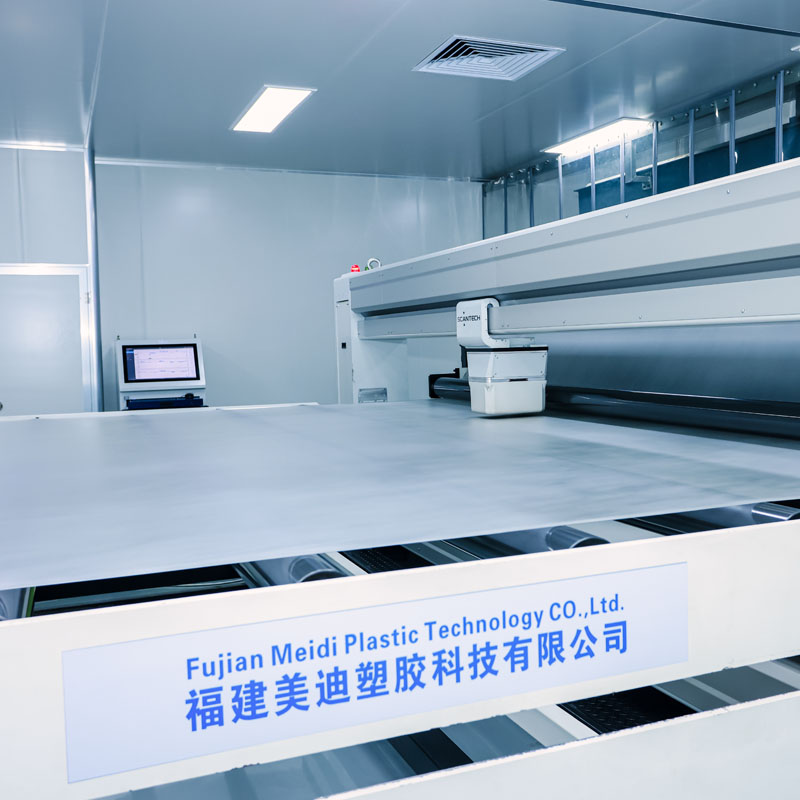

Fujian Medi ionoplast interlayer (known as R-SGP® ionoplast interlayer) is a co-polymer of sodium methacrylate and ethylene, representing the latest invention in modern ultra-safe glass interlayers. It has a shear modulus 50 times that of PVB and a hardness 100 times that of PVB. It can be rolled up to a width of 3700mm. The R-SGP® ionoplast interlayer not only has excellent non-toxic, odorless, transparent, and high bonding performance, as well as good impact resistance, but also possesses outstanding comprehensive properties, such as explosion-proof, bulletproof, hurricane-resistant, heat-resistant, cold-resistant, radiation-resistant, and anti-weathering. It is an ideal selection for transparent materials in structural glass for unmanned sentry post construction and explosion-proof equipment in harsh environments.

Production performance

1. Anti-intrusion safety and original rigidity maintained after breakage.

Ordinary PVB laminated glass has significant bending and deformation, with the risk of complete detachment when broken. However, laminated glass made with thick plate glass and R-SGP® ionoplast interlayer can be used as structural glass. After breakage, it maintains its original rigidity and can withstand a certain amount of load without falling apart. This greatly increases the safety of glass structures.

2. High toughness and shear modulus, outstanding mechanical properties.

R-SGP®ionoplsat interlayer has high toughness, and its shear modulus is 50 times higher than PVB, and its hardness is 100 times higher than PVB. Performance tests conducted by the National Laboratory and the Ministry of Public Security's First Research Institute show that laminated glass made with Fujian Meidi ionoplsat interlayer of the same thickness performs similarly to bulletproof glass made with polycarbonate.

3. It has good edge stability and is compatible with structural adhesives.

PVB interlayers are susceptible to moisture, which can cause the glue to loosen and separate. Therefore, it is necessary to seal the exposed edges. On the other hand, R-SGP® ionoplast interlayer has excellent edge stability, are insensitive to water, have low absorption, and do not separate or loosen when used under exposed conditions. It has good compatibility with neutral structural adhesives, and no edge sealing is required for the glass edges.

4. Colorless and transparent, resistant to discoloration.

The R-SGP® ionoplast interlayer is colorless and transparent, with good weather resistance and not prone to yellowing. Even after years of use, the R-SGP® ionoplast interlayer maintains its original transparency, while the interlayer in ordinary PVB gradually becomes more yellow during use.

In comparison to similar products, what are the advantages

A:Dual Patents for Pattern Design and Pattern Appearance

(Pattern Patent: ZL202222061978.1 Pattern Appearance Patent: 202230837733.6)

It has better air exhaust performance than any other similar product. The temperature difference range of the glass surface at the exit of the pressure roller is wider than that of the entrance brand. The surface temperature of the glass at the exit of the pressure roller of the entrance brand is around 60℃ to 65℃, with a temperature difference of less than plus or minus 3℃. However, R-SGP® ionoplast interlayer still maintains good air exhaust performance with a surface temperature of 62℃ to 75℃ and a temperature difference of plus or minus 5℃. The thin glass plate can be rolled at a speed of up to 2000mm/minute while still maintaining good air exhaust performance, which is equivalent to the speed of rolling PVB laminated glass, thus improving production efficiency.

B : Through rigorous impact testing in the field of strength and mechanics.

Concrete pylon test: A laminated glass made of 6mm+toughened R-SGP® ion-exchange interlayer film 1.52mm+6mm, clamped by 6 supporting points, can withstand an impact of 1380 joules from a concrete pylon without cracking or delamination, maintaining its original rigidity.

Unilateral support: After 4 hours of natural placement at the ambient temperature of 23℃ to 30℃, the structure of the glass sample is laminated glass made of 6mm+2.28mmR-SGP® ionoplast interlayer +6mm tempered glass is dropped and impacted with 45KG pellet bag at a height of 1200mm from the impact point, and the glass tilt is placed naturally 2 minutes and 1 hour after the impact Have not changed.

Extensively used:

1

Structural glass.

Transparent booths and unmanned guard posts in use.

2

Facades

Large-scale high-rise buildings, such as premium office towers, hotels, and shopping centers, are commonly utilized.

3

Bullet proof glass

Laminated glass made with R-SGP® ionoplast interlayer of the same thickness performs equally to laminated glass made with polycarbonate interlayer.

4

Dome protection.

Protect against high altitude debris.

5

Unilateral support

Can be used as balcony or villa railings without frames, with glass edges that require no sealing treatment.

6

Typhoon Resistance

Can withstand a Category 17 hurricane and a 7.0 magnitude earthquake.

7

Igh-speed train safety.

Its hardness and toughness provide excellent safety performance for bullet train glass.